mechanical testing of soft polymers|mechanics of soft polymers : companies ASTM and ISO standards for mechanical testing of polymers. The ASTM Standards for testing of plastics include ASTM D638 for tensile test, . covers the relative hardness of soft materials, usually elastomers. This test measures the depth of penetration of an indenter into the material under specified load (force) and time [107]. ASTM D785 . 13 de mai. de 2020 · The Agent Destiny online slot from Play'n Go cuts its theme cut right out of the famed spy films and television shows of the past mixed with the animation reminiscent of the current cult TV show “Archer.” The overall look is an homage to comic book artist Adam Hughes. The game carries vibrant visuals, stunning symbols and a .

{plog:ftitle_list}

webO gráfico a seguir exibe os preços, nos últimos meses, do Hyundai HB20 Comfort 1.6 Flex 16V Automático 2015. Histórico de Preços A tabela mantém arquivado todos os preços deste ano/modelo, registrando a variação mensal e acumulada.

Therefore, in this section, the test procedure for biaxial test characterization of soft polymers will be briefly reviewed including loading conditions i.e., pure shear (PS), equi-biaxial (EB) and unequal-biaxial (UB), strain rate, strain amplitude, clamping systems, and the final .The scientific scope of this COLLECTION is dedicated to novel and advanced testing methods establishing a connection to fundamental scientific principles that even show how test results .

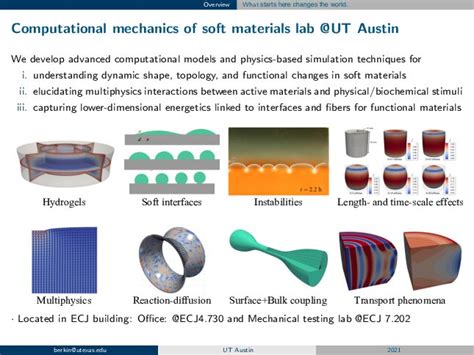

soft material mechanics

Bulge test, also known as the inflation test, is the most common type of biaxial test conducted on elastomers and thin films (Fig. 1 b).However, thickness variations throughout the membrane during pressurisation result in severe nonlinear mechanical behaviour i.e. inhomogeneous stress and strain distributions, in particular at large strain amplitudes so that . ASTM and ISO standards for mechanical testing of polymers. The ASTM Standards for testing of plastics include ASTM D638 for tensile test, . covers the relative hardness of soft materials, usually elastomers. This test measures the depth of penetration of an indenter into the material under specified load (force) and time [107]. ASTM D785 . In this chapter, we present the current research program of dynamic mechanical behaviour of polymer materials. Polymers typically have low strength, stiffness and wave impedance, making it challenging to obtain . Conventional mechanical testing procedures such as tensile, bending, and fracture toughness are used to outline the static mechanical performance of SMPs. The cyclic mechanical testing facilitates the evaluation of shape-memory parameters such as shape fixity (R f) and shape recovery (R r) ratio. In a recent development, nanoindentation .

A hybrid model to determine mechanical properties of soft polymers by nanoindentation The development of a hybrid model – JKR and Hertz- to analyze the elastic modulus of soft polymers (PDMS) . As nanoindentation continues to rise in utility for testing soft polymers, it becomes imperative to recognize the assumptions and limitations in the .

The mechanical properties of polymers are of primary and fundamental importance in determining their applicability in any technological field. The mechanical properties of polymers involve their behavior under the application of stress and include the extent of stretching, bending, hardness, softness, etc. In this work, we study the nonlinear behavior of soft photocured polymers typically used in 3D-printing. We perform experimental testing of 3D-printed samples cured at various controlled light intensities. The experimental data show the dependency of the material elasticity and rate-sensitivity on the curing light intensity. The proposed nonlinear fractal viscoelastic model is used to fit the mechanical test observations of a wide range of soft materials reported by several research groups in the past for a myriad testing conditions. Mechanical characterization of different types of soft materials such as hydrogels, xerogels, and sponges has been extensively .Manufacturers of soft polymer products, as well as suppliers and processors of polymers, raw materials, and compounds or blends are compelled to use predictive and advanced laboratory testing in their search for high-performance soft polymer materials for future applications. The collection of 12 publications contained in this edition therefore presents different methods used .

Our Polymer Mechanical Testing Services. Our laboratories are equipped to test the mechanical properties of both polymer materials and polymer-based components. With custom-built test fixtures, we can provide critical data about strength, resistance and longevity under a wide range of loads or stress conditions. We work with you to design and .Polymers exhibit a wide range of stress-strain behaviors as shown in the figure below. The brittle polymer (red curve) elastically deforms and fractures before deforming plastically. The blue curve is a plastic polymer and is similar to curves for many metals. Its behavior begins in the linear elastic deformation region.

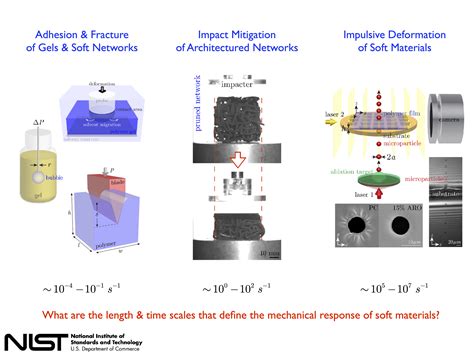

Numerous factors affect various mechanical properties of polymers, in cluding molecular weight, processing, extent and distribution of crystallinity, composition of polymer, and use temperature. Chapter 3 describes basic mechanical testing procedures. This chapter describes various structural-related factors which affect polymeric mechanical3.3. Mechanical Results of Soft Tissue-Mimicking Polymers The most significant stress–strain curves obtained after the tests are shown in Figure 12. The mechanical properties (mean ± std), as well as R2 and CV% of the soft tissue-mimicking polymers, are summarized in . Determination of dynamic tensile response of soft materials has been a challenge because of experimental difficulties. Split Hopkinson tension bar (SHTB) is a commonly used device for the characterization of high-rate tensile behavior of engineering materials. However, when the specimen is soft, it is challenging to design the necessary grips, to measure the .

1 Introduction. Due to their inherent softness and compliance, soft robots are often used for grasping delicate objects, [1, 2] including fruits and vegetables in food packaging, [3, 4] agriculture, [] electronics, and even . Poor adhesion and mechanical mismatches may cause interface failure of soft devices. Here, authors report a supramolecular solvent-doped, soft, adhesive, yet conductive polymer composite for . Which is the most used mechanical test? Tensile testing is the most used mechanical engineering test. The fundamental type provides manufacturers with parameters such as stress, strain, yield deformation, and . Indentation testing is a widely-used method for mechanical characterisation of many materials, including polymers. The most important parameter drawn from an indentation test is hardness, commonly described as a material’s resistance to local surface deformation.

Using a conventional mechanical testing apparatus equipped with a thermochamber, a single, fixed experimental setup can be used to simultaneously control the stress, strain and temperature during . The present study investigates the strain-rate-dependent mechanical performances of three different kinds of polymers in low-temperature applications, including plastic piping systems. Recently, lightweight constructions have been increasingly used in ship and offshore structures because using low-density materials reduces the structural weight of .Read the latest articles of Polymer Testing at ScienceDirect.com, Elsevier’s leading platform of peer-reviewed scholarly literature . select article Measurement of quasi-static and dynamic mechanical properties of soft materials based on instrumented indentation using a piezoelectric cantilever . select article Distributed optical sensing . Dynamic mechanical analysis (DMA) or dynamic mechanical thermal analysis is a thermal testing technique used extensively in the polymer and rubber industries. It involves applying an oscillatory force or deformation to a material and monitoring the response.

The mechanical behavior for polymers is very sensitive to the deformation rate of the impact test. Thus we are developing and applying several novel measurements that can study the mechanical response of the polymer at different deformation rates .

Soft polymeric materials are finding greater use in micro-devices and biomedical engineering applications (McDonald and Whitesides, 2002).For instance, polydimethylsiloxane (PDMS) is one of the most widely used materials in microfluidics (Whitesides, 2006), and polyacrylamide can be used as a soft substrate (Pelham and Wang, 1997, Qin et al., 2007, . A limited number of review papers address the complications associated with testing soft, hydrated or viscoelastic biomaterials (Table 1). In the seminal nanoindentation review paper on nanoindentation in biomaterials, Ebenstein and Pruitt emphasize the susceptibility of adhesive interaction between the probe and sample (Ebenstein and Pruitt, 2006).

Diagnosing diseases and modeling their progression within soft tissues is another prominent application of soft tissue characterization. Mechanical properties reveal a great deal about the overall health of soft tissues and changes to them can be used as a biomarker for early disease detection (Ansardamavandi et al., 2016).Changes in mechanical properties usually . The topical section "Advanced Testing of Soft Polymer Materials" focuses on high-value manuscripts related to sophisticated characterization methods of soft polymer materials. . topics on advanced testing methods and equipment should illustrate advances in areas such as mechanical multi-axis testing, dynamic-mechanical and thermal analysis .

mechanics of soft polymers

Synchronous Thermal Analyze fabrication

mechanical properties of soft materials

14 de out. de 2021 · Nataly Galdino, de 21 anos, foi picada no lábio superior por inseto enquanto dormia. Ela ficou com os lábios muito inchados e teve que procurar atendimento em um hospital.

mechanical testing of soft polymers|mechanics of soft polymers